The urgency surrounding per- and polyfluoroalkyl substances (PFAS) contamination has created a rush to implement treatment solutions across the water industry. However, this haste often leads to costly assumptions about the “best” removal technology, potentially resulting in higher capital expenditures and inflated lifecycle costs. The reality is that effective PFAS removal requires a nuanced understanding of multiple variables and a strategic approach tailored to specific site conditions.

Understanding the Four Primary PFAS Removal Technologies

Granular Activated Carbon (GAC)

GAC systems excel in applications where volatile organic compounds (VOCs) are present alongside PFAS contamination. This technology offers proven effectiveness but requires larger footprints compared to other solutions, making it ideal for facilities with adequate space and specific water quality profiles.

Ion Exchange (IX)

Ion exchange technology provides efficient PFAS removal in a compact system design. However, IX media can be sensitive to oxidizing agents like chlorine, making it less suitable for applications requiring pre-oxidation treatments for iron and manganese removal.

FLUORO-SORB Media

This specialized media technology demonstrates superior performance in challenging water conditions, particularly where high levels of iron and manganese necessitate pre-treatment with oxidizing agents. FLUORO-SORB media maintains its effectiveness even in the presence of chlorine, making it versatile for complex water quality scenarios.

High Recovery Flow-Reversal Reverse Osmosis (FR-RO)

FR-RO systems offer exceptional performance in high-salinity environments while providing protection against emerging contaminants. These systems produce concentrated reject water that requires proper disposal management but deliver comprehensive treatment capabilities.

Critical Factors Influencing Technology Selection

Water Quality Matrix

The background composition of source water significantly impacts technology selection. According to industry experts at Water Online, the presence of multiple contaminants often dictates which PFAS removal technology will be most effective. For instance, waters with high iron and manganese levels may require oxidation pre-treatment, which can damage certain downstream treatment media.

Specific PFAS Compounds and Treatment Goals

Different PFAS compounds respond variably to treatment technologies. State-specific regulations further complicate the selection process, as treatment goals vary significantly across jurisdictions. Each media solution must be evaluated against target PFAS parameters to ensure regulatory compliance.

System Footprint and Operational Constraints

Physical space limitations play a crucial role in technology selection. While GAC systems require larger footprints for equivalent flow rates, IX and FLUORO-SORB systems offer more compact designs suitable for space-constrained facilities.

Economic Considerations and Lifecycle Analysis

Capital and Operating Expenses

Effective PFAS treatment requires comprehensive economic analysis beyond initial capital costs. Operating expenses including media replacement, labor requirements, energy consumption, and maintenance must be evaluated over the system’s entire lifecycle.

Waste Disposal Challenges

Post-treatment waste management represents a significant operational consideration. Exhausted media requires specialized disposal in accordance with local and state regulations, while RO systems generate concentrated reject water requiring appropriate handling. As noted in recent industry analysis from Water Online, experienced solution providers offer turnkey disposal services to address these challenges.

The Importance of Expert Partnership

Customized Solution Development

Effective PFAS removal demands more than equipment selection—it requires comprehensive understanding of process design integration. Solution providers must analyze site-specific conditions and engineer tailored approaches rather than applying one-size-fits-all solutions.

Long-term Service Considerations

Successful PFAS treatment extends beyond initial installation. Comprehensive service offerings including operator training, media disposal support, and emergency treatment services ensure long-term operational success. Treatment-as-a-Service (TaaS) models provide flexible solutions for facilities requiring rapid deployment or interim treatment capabilities.

Strategic Approach to PFAS Treatment

The complexity of PFAS removal necessitates a strategic approach that considers multiple variables simultaneously. Water quality characteristics, regulatory requirements, physical constraints, and economic factors must be evaluated collectively to identify optimal treatment solutions.

Rather than assuming a preferred technology, successful PFAS treatment begins with comprehensive site assessment and expert consultation. This approach, as detailed in comprehensive industry resources like Water Online, ensures that treatment systems are designed for specific applications while optimizing both performance and cost-effectiveness.

The imperative for PFAS removal continues to intensify, but rushing to implement treatment without proper evaluation can result in suboptimal outcomes. By partnering with experienced solution providers and conducting thorough site-specific analysis, water treatment professionals can develop effective, economical PFAS removal strategies that meet regulatory requirements while minimizing lifecycle costs.

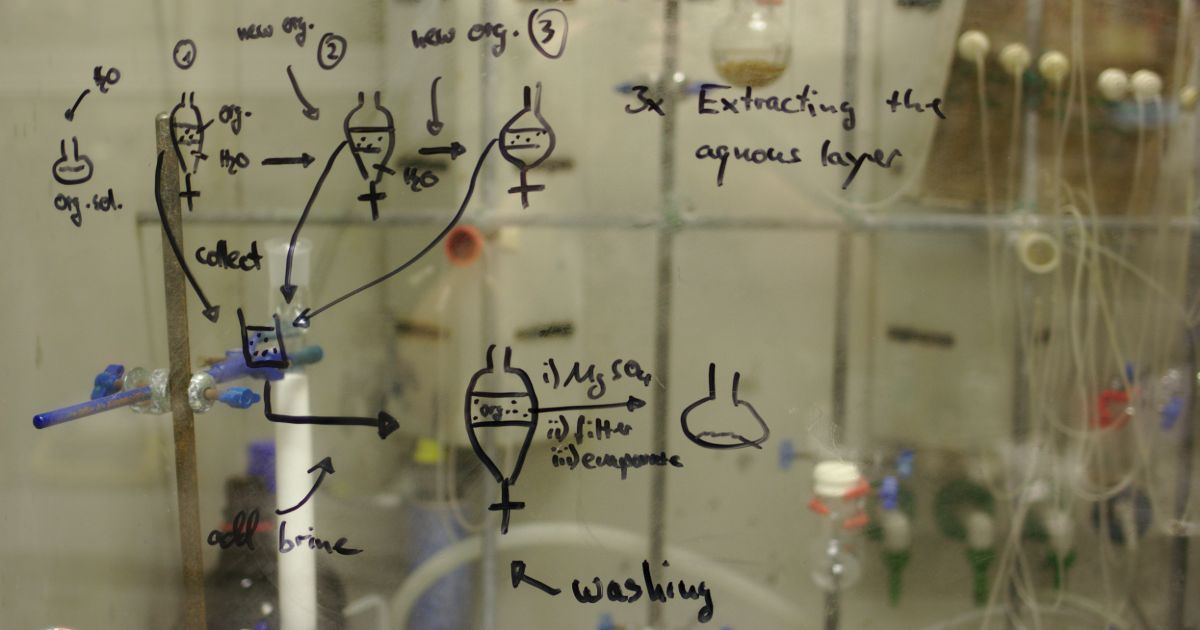

Photo by Chromatograph on Unsplash